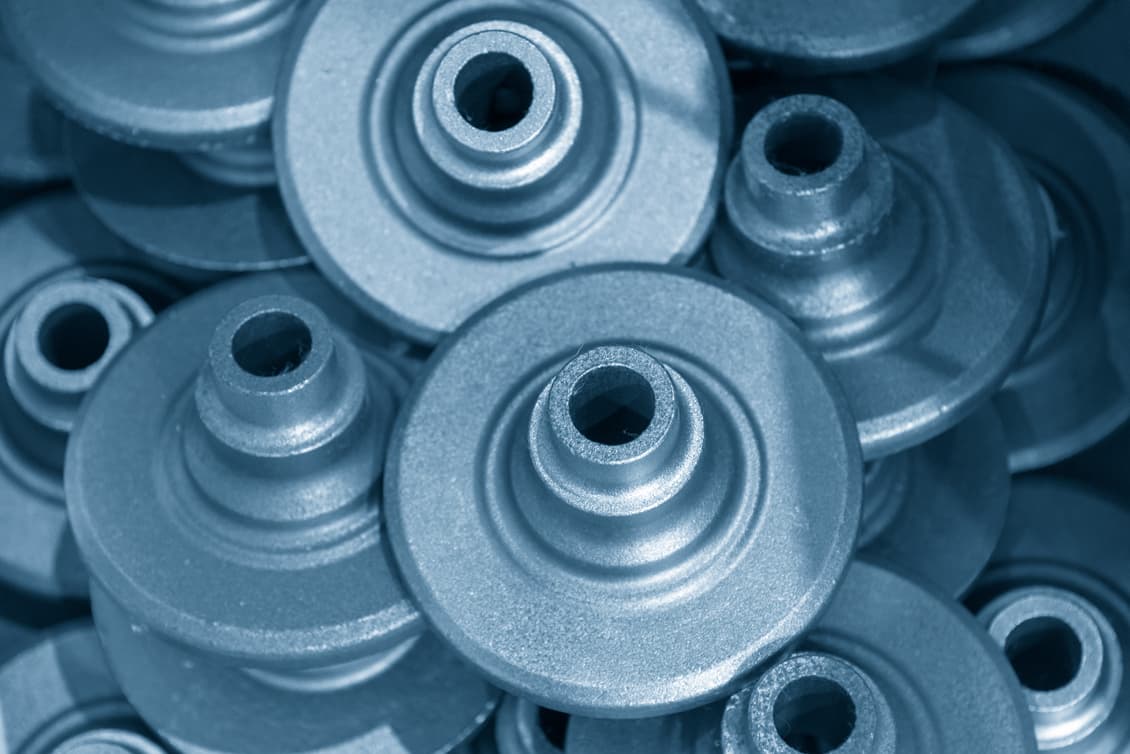

Rough Casting Surface

Problem Description:Surface roughness can reduce the quality of the finished product and the efficiency of subsequent processing, and is often caused by uneven ceramic shell surfaces or inclusions in the molten metal.

Solution:

- Use fine-grained surface ceramic powder and keep the ceramic slurry stirred evenly to prevent sedimentation.

- Optimize the dewaxing and roasting procedures to avoid carbonization of residual wax or poor sintering.

- Control casting temperature and pouring speed to reduce slag inclusion and slag marks.